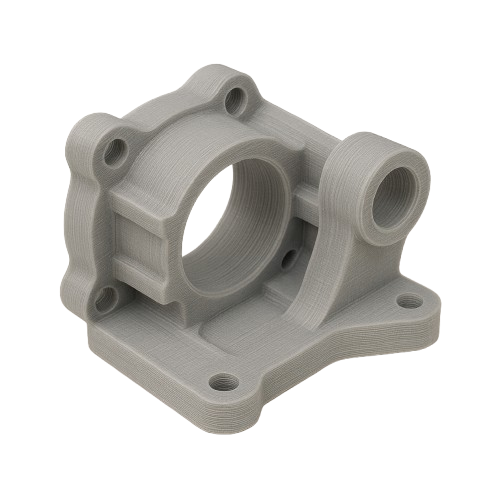

India’s 3D printing scene is moving fast. In 2024, the additive manufacturing market was already valued at around USD 707 million (₹5,915 crore), and analysts expect it to expand at an annual rate of about 21.7% over the next ten years. What’s exciting is that this growth isn’t limited to big factories—it’s reaching students, hobbyists, and small businesses across the country.

If you’ve gone through my beginner’s guide to 3D printers, you know the machine itself is just the starting point. Without filament, a printer is nothing more than an idle box. Filament is the core material for FDM printing, and the type you choose directly decides whether your project turns out sturdy and polished—or ends up fragile and unusable.

Government initiatives are pushing this shift further. The National Strategy for Additive Manufacturing and Make in India 2.0 have set clear targets: building 100 new startups and training 100,000 skilled professionals by 2025. Alongside that, affordable desktop printers priced between ₹15,000–₹35,000 and the rise of community makerspaces in tier-1 and tier-2 cities are making 3D printing accessible to thousands of first-time creators.

Filament is also where most of the money goes—often over 75% of material costs in a typical printing setup. Indian suppliers like WOL3D, Numakers, and Dream Polymers have reduced prices by 20–30% compared to imports, while international names such as eSUN and Creality are offering improved variants like PLA+, ABS+, and PETG+. The result is more choice and better value for Indian makers.

You can already see the impact in real projects. Agnikul Cosmos is using 3D printing for rocket parts that cut production costs nearly in half. IIT campuses report that about 70% of STEM students now prototype with 3D printers. Healthcare startups are creating affordable prosthetics and surgical models, proving that this isn’t just hype—it’s changing lives.

This guide will walk you through the most popular filament types available in India—PLA, ABS, and PETG. I’ll compare their pricing, strengths, and weaknesses so you can figure out which one fits your work best. By the time you’re done, you’ll know how to get the best results from your printer without wasting time, money, or effort.

The 3 Most Popular Filament Types for Indian Makers

When you’re getting started with 3D printing in India, you’ll notice three filament types that almost every maker relies on: PLA, ABS, and PETG. Each one behaves differently, carries its own price range, and works better for certain kinds of projects. PLA is popular because it’s easy to print with and budget-friendly. ABS is tougher and heat-resistant but can be trickier to handle. PETG sits in the middle—strong, flexible, and less prone to warping. Knowing how these compare will help you pick the right material and get consistent results from your printer.

PLA (Polylactic Acid) – The Beginner’s Best Friend

PLA is usually the starting point for most beginners in India who want to try 3D printing. It’s a plastic made from renewable resources such as corn starch, so it’s considered one of the safer and more environmentally friendly choices compared to petroleum-based filaments. The real reason it’s so popular though is its ease of use—PLA prints at relatively low temperatures, doesn’t require a heated chamber, and gives reliable results even on budget printers. That makes it the go-to option for hobbyists and first-time makers who want quick, clean prints without too much hassle.

Pros

✅ Easy to print

✅ Low cost & widely available

✅ Biodegradable & plant-based

✅ Minimal warping or fumes

Cons

⚠️ Brittle and not durable

⚠️ Low heat resistance (~60°C)

⚠️ Absorbs moisture from air

⚠️ Not resistant to UV light

Numakers

₹625 – ₹799

WOL3D

₹850 – ₹999

eSUN

₹1,318 – ₹1,900

Creality

₹1,300 – ₹1,900

ABS (Acrylonitrile Butadiene Styrene) – The Durable Workhorse

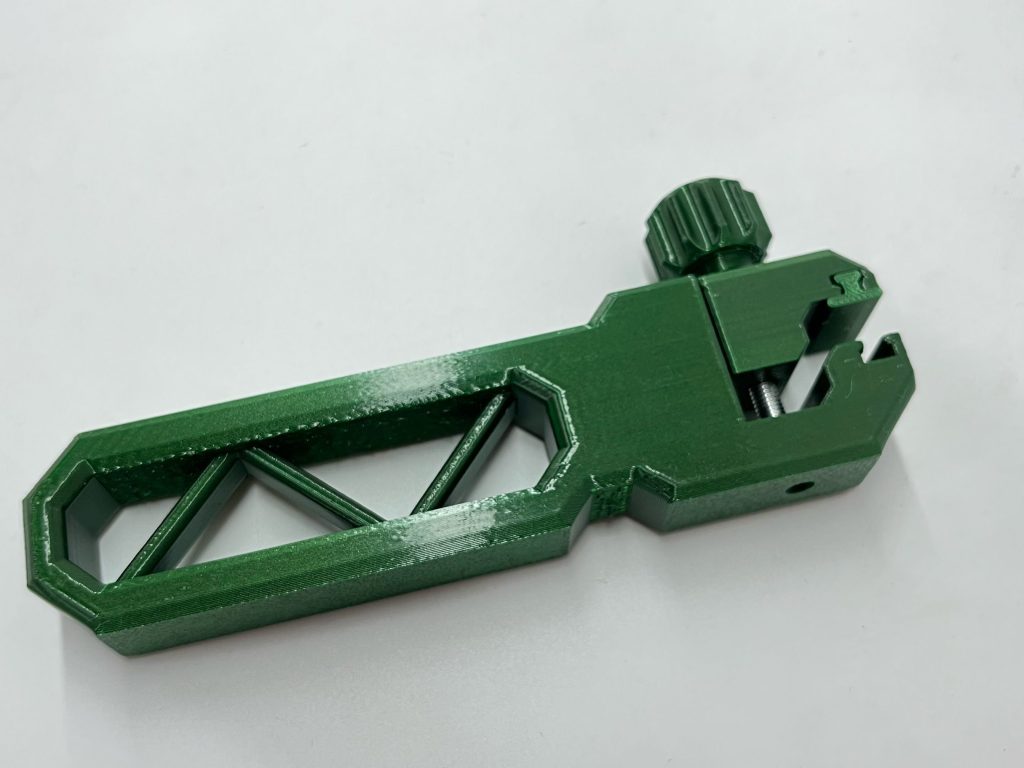

ABS is a solid pick if you need parts that can take a beating and hold up under higher temperatures. Compared to PLA, it’s stronger and more durable, which is why it’s a favorite for functional prints like enclosures, brackets, or anything exposed to heat. The trade-off is that it demands more attention during printing—controlling temperature, reducing warping, and sometimes using an enclosure to get consistent results.

Pros

✅ Stronger and more durable than PLA

✅ Withstands higher temperatures

✅ Suitable for mechanical parts

✅ Good for phone cases, enclosures, etc.

Cons

⚠️ Prone to warping without proper setup

⚠️ Emits fumes while printing

⚠️ Requires a heated bed

⚠️ Often needs an enclosure

FibReel

₹710 – ₹899

Protoprint (recycled)

₹800 – ₹1,100

Creality

₹1,200 – ₹1,500

eSUN ABS+

₹1,400 – ₹1,600

PETG (Polyethylene Terephthalate Glycol) – The Balanced All-Rounder

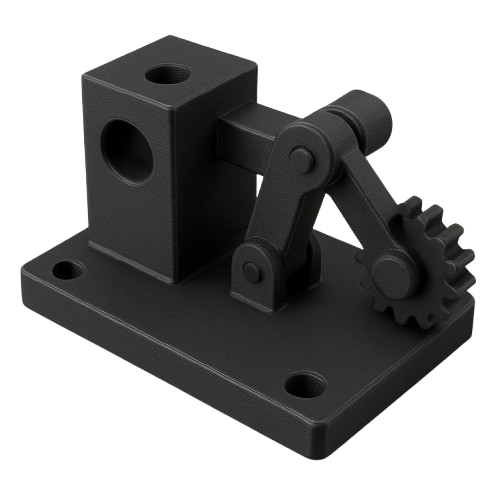

PETG sits right between PLA and ABS in terms of performance. It’s stronger and more durable than PLA, while still being much easier to work with than ABS. On top of that, it can handle moderate heat without deforming, which makes it a reliable option for printing practical parts like brackets, enclosures, or everyday tools. That balance of toughness, ease of use, and heat resistance is why many makers reach for PETG when they want functional prints that don’t crack under pressure.

Pros

✅ Stronger and less brittle than PLA

✅ More forgiving than ABS (less warping)

✅ Food-safe variants available

✅ Excellent layer adhesion

Cons

⚠️ Slightly harder to print than PLA

⚠️ Can be prone to stringing

⚠️ Bonds too strongly to some surfaces

⚠️ Absorbs moisture from air

AlmightyFila

₹750 – ₹1,000

Dream Polymers

₹800 – ₹1,100

Creality CR-PETG

₹1,075 – ₹1,200

eSUN PETG+

₹1,200 – ₹1,400

Comparative Table: PLA vs ABS vs PETG

Filament Comparison: PLA vs. ABS vs. PETG

| Feature | PLA | ABS | PETG |

|---|---|---|---|

| Best For | Beginners, visual prototypes, and non-functional models. | Durable, functional parts that need high temperature and impact resistance. | Functional parts needing strength and flexibility, with better ease-of-printing than ABS. |

| Strength | Medium (Brittle) | High (Impact Resistant) | High (Less Brittle) |

| Flexibility | Low | Medium | Medium |

| Heat Resistance | Low (~60°C) | High (98–100°C) | Medium (70–80°C) |

| Ideal Uses | Figurines, architectural models, display items, low-stress parts. | Phone cases, automotive fixtures, enclosures, mechanical components. | Water-resistant containers, storage boxes, mechanical gears, protective parts. |

| Pros |

|

|

|

| Cons |

|

|

|

| Avg. Cost in India | Lowest (₹625 – ₹1,900) | Mid-Range (₹710 – ₹1,600) | Mid-Range (₹750 – ₹1,400) |

Where to Buy 3D Printing Filaments in India

Buying the right filament isn’t just about picking PLA, ABS, or PETG—it’s also about where you buy it from. A good supplier can make the difference between smooth, reliable prints and constant frustration. Reliable sellers don’t just ship you a spool; they make sure it’s genuine, stored properly, and delivered in a way that protects it from India’s humidity. To save you time and mistakes, I’ve pulled together some of the most trusted places in India to buy 3D printing filaments. Each one suits different kinds of buyers, whether you’re a hobbyist experimenting at home or a small business running regular print jobs.

Dedicated Online Stores

Specialized retailers focusing on 3D printing supplies, offering reliability and a wide range of products for hobbyists and professionals.

WOL3D

As one of India’s largest 3D printing retailers, WOL3D offers an extensive catalog of printers, accessories, and a massive variety of filaments from domestic and international brands.

3D Bazaar

A focused marketplace for 3D printing enthusiasts, known for its curated selection of high-quality materials, strong community focus, and excellent customer support.

Visit StoreThink3D

More than a store, Think3D is a service provider offering end-to-end solutions from material sales to on-demand 3D printing, catering primarily to professionals and businesses.

Visit StoreSpecialized shops like WOL3D, 3D Bazaar, and Think3D have built their entire business around 3D printing. Instead of spreading themselves thin with general electronics, they focus only on filaments, printers, and related tools. That focus shows in what they offer—stock from both Indian and international brands, covering affordable names such as Numakers all the way up to well-known imports like eSUN and Creality.

Most filaments from these retailers are priced between ₹700 and ₹1,800 per kilogram, depending on the material and brand. Beyond price, what really sets them apart is reliability. They tend to handle storage better (important for moisture-sensitive filaments), provide clearer product specifications, and process replacements faster if something goes wrong. For hobbyists who print regularly or professionals running client projects, these small details often make the difference between a smooth print and wasted hours.

Major E-Commerce Platforms

If you’re just starting out, Amazon India and Flipkart are usually the simplest places to pick up filament. They carry plenty of options, ship quickly to most tier-1 and tier-2 cities, and prices cover the full range—from basic PLA spools that start around ₹650 to imported brands that can reach ₹2,000. The trade-off is consistency. Not every seller stores filament properly, so you may run into spools that absorb moisture or feel inconsistent in quality. The safest approach is to stick with sellers who have strong reviews and repeat buyers. For casual hobbyists or anyone testing their first 3D printer, these platforms are a convenient first step.

Local Distributors & Maker Communities

In bigger cities, you’ll also find smaller distributors or local maker groups—sometimes FabLabs, university labs, or independent collectives—that resell filament. The selection is usually narrower than what you’d see online, but the prices can be 10–15% lower, especially if you’re buying in bulk or splitting a box with friends. Beyond the savings, the real benefit is the community: these groups often share practical tips, troubleshooting advice, and even access to tools you might not own yourself. If you’re a student or planning frequent prints, these networks can be a smart and supportive way to source materials.

Mastering Filament Storage in India’s Humid Climate

India’s climate is naturally humid—most regions stay between 60% and 80% humidity almost the whole year. That’s a real problem for filaments like PLA, ABS, and PETG, because these materials soak up moisture from the air. The result? A spool that once printed beautifully can suddenly snap mid-print, leave messy strings, or fail to stick to the bed. The tricky part is that this damage can start after just a few hours of exposure. The good part is you don’t need fancy equipment to prevent it. With proper storage—dry boxes, airtight containers, or even simple silica packs—you can keep your spools safe and get the same reliable, high-quality results every time.

Simple DIY Solutions

For beginners on a budget, DIY storage can go a long way:

- Vacuum-Sealed Bags: Affordable and widely available online. They keep air out, and silica gel packets inside help absorb residual moisture. Perfect for occasional users.

- Airtight Bins: Using plastic containers with tight lids and silica packets gives you a low-cost, reusable storage option for multiple spools.

These solutions are easy to set up at home and ideal if you’re experimenting with a few rolls of filament.

Professional Products

If you’re printing regularly or working on commercial projects, professional-grade storage offers greater peace of mind:

- Filament Dry Boxes: Purpose-built containers that not only store but also allow you to print directly from inside, keeping spools dry during long jobs.

- Filament Dryers: Electric devices that actively remove moisture, usually in 4–6 hours. Especially useful for salvaging spools that have already absorbed water.

While these products cost more upfront, they save money in the long run by reducing failed prints and extending filament life.

From Spool to Showpiece: Understanding the Final Look and Feel of Your Prints

3D printing doesn’t stop being interesting once the machine cools down. The type of filament you load into your printer plays a huge role in what comes out at the end. Strength and durability are the obvious factors, but there’s more to it—how the surface feels, how shiny or matte it looks, whether it’s translucent or opaque, and even whether it carries a faint odor. Standard filaments cover most everyday needs, while specialty ones can change the whole personality of a print. Choosing the right material is what turns a basic model into something that feels finished and intentional.

Standard Filaments: Your Go-to Finishes

PLA (Polylactic Acid)

PLA prints with a semi-gloss to matte surface…

Mastering the Finish: How Print Settings Matter

Even with the right filament, your print settings can make or break the finish:

- Nozzle Temperature: Slightly higher temps improve bonding and smoothness, while lower temps sharpen detail but risk gaps.

- Print Speed: Slower speeds (20–40 mm/s) give smoother surfaces, while faster speeds show more layer lines.

- Layer Height: Fine layers (0.1–0.15 mm) create polished, detailed surfaces—ideal for Silk PLA or clear PETG. Thicker layers (0.2–0.3 mm) add speed but emphasize texture, which can complement wood PLA.

- Cooling: PLA and Silk PLA benefit from strong cooling for crisp detail, while ABS and PETG often need reduced fan speeds for strong layer adhesion.

By tuning these settings alongside your filament choice, you can turn a raw spool into a showpiece that looks professional and performs exactly as intended.

The Future of 3D Printing in India: A Look at Tomorrow’s Materials

India’s 3D printing filament market has changed a lot in the last few years. Materials like PLA and ABS, which once had to be imported at premium prices, are now being produced locally and sold across popular e-commerce platforms. Today, you’ll typically find PLA between ₹625–₹800 per kilo, while ABS averages around ₹710–₹900. Not long ago, the same spools were 30–40% more expensive. The price shift isn’t random—it comes from more Indian manufacturers stepping in, stronger competition, and smoother supply chains that cut unnecessary costs.

This drop in pricing has made 3D printing far more approachable. Students can afford to experiment with school projects, hobbyists can print from their homes without breaking the bank, and small businesses can create prototypes or custom parts at a reasonable cost. What used to feel like a costly, niche hobby is now turning into a practical tool that supports creativity, learning, and even entrepreneurship.

From Eco-Friendly to High-Performance: The Rise of New Material

India’s filament market is no longer just about standard PLA and ABS. Two distinct directions are shaping the future: eco-friendly options and high-performance industrial materials.

Eco-Friendly Filaments

Demand for biodegradable PLA made from corn and sugarcane is growing by nearly 25% each year, supported by Atmanirbhar Bharat initiatives that encourage local manufacturing. Startups such as Protoprint are experimenting with recycled ABS and PETG, helping manufacturers cut costs by up to 15% while lowering carbon emissions. Researchers at IIT Bombay are also developing PHA-jute composites—a fully biodegradable filament projected to enter the market by 2026. This line of work is important for companies seeking both affordability and environmental responsibility.

High-Performance Filaments for Industry

On the industrial side, demand is shifting toward materials built for strength and durability. Carbon-fiber-reinforced PETG, sold in the range of ₹1,850–₹4,800 per kg, is already being tested by Mahindra & Mahindra to produce lightweight automotive brackets, showing up to 40% weight savings compared to conventional parts. At the higher end, PEEK filament—costing nearly ₹7,500 per kg—is being adopted in aerospace, oil & gas, and even medical implant production, thanks to its heat resistance and structural reliability. Companies such as Agnikul Cosmos highlight this shift, with advanced facilities dedicated to 3D printing rocket components, proving just how central these premium materials are becoming to India’s industrial growth.

FAQ: 3D Printing Filaments for Indian Users

What materials are most common in FDM 3D printing?

The three most widely used are PLA, ABS, and PETG. PLA is the clear favorite, holding about 22.7% of the global market because it’s simple to print with and doesn’t demand advanced hardware. ABS is tougher, often chosen for parts that need durability. PETG sits in the middle—it has the strength of ABS but keeps the easy-to-print nature of PLA. Beyond these, you’ll also find TPU (flexible prints like phone cases), nylon (extra strength), and blends that include wood, carbon fiber, or metal powders.

Which filament is the cheapest and easiest for beginners in India?

If you’re starting out, go for PLA. It’s affordable and works reliably even on basic printers. Local options like Numakers PLA start around ₹625/kg and WOL3D at ₹599/kg. It prints between 180–220°C, rarely warps, doesn’t give off harmful fumes, and can often be used without a heated bed—making it the most beginner-friendly choice.

What’s the difference between thermoplastics (PLA/ABS/PETG) and resins?

- Thermoplastics (used in FDM printers): They can be melted, reshaped, and are strong enough for functional parts.

- Resins (used in SLA printers): They cure permanently under UV light. The detail level is unmatched, which is why resin is so popular for jewelry and miniatures, but the trade-off is brittleness and higher cost.

Think of it this way—FDM is great for strength and everyday utility, while SLA is for ultra-fine detail.

Why does stringing or oozing happen, and how can I fix it?

Stringing happens when melted plastic leaks out while the nozzle moves. Usual culprits:

- Temperature too high

- Retraction not set correctly

- Travel speed too low

- Filament absorbing moisture

Quick fixes you can try:

- Increase retraction distance step by step (1 mm at a time)

- Drop the nozzle temperature by 5–10°C

- Raise travel speed to around 150–200 mm/s

- Dry the filament if it’s been exposed to humidity

Why does the nozzle clog, and what’s the fix?

Clogs are usually caused by dusty filament, switching materials without cleaning, printing at the wrong temperature, or the nozzle being too close to the bed.

How to deal with it:

- Partial clog: Run cleaning filament or do a cold pull

- Full clog: Heat the nozzle, carefully poke with a thin needle, then follow up with cleaning filament

Prevention tip: Store filament in dry conditions and clean the nozzle whenever you change material.

How do I fix weak layer bonding or cracks in prints?

Try these adjustments one at a time:

- Raise print temperature slightly (5–10°C)

- Slow down the print speed to around 35–50 mm/s

- Reduce layer height so layers press together more firmly

- Bump up flow rate by about 5% if extrusion seems weak

- Use an enclosure when printing ABS or other temperature-sensitive materials

How can I tell what type of filament I have if the spool isn’t labeled?

A few simple tests work well:

- Acetone test: ABS dissolves/shines; PLA softens; PETG barely reacts

- Smell test: PLA smells slightly sweet, ABS has a chemical odor, PETG is almost odorless

- Flexibility test: PETG bends and springs back; PLA and ABS are more rigid

- Heat test: PLA softens around 50–60°C, ABS and PETG need more heat

How should I dry different filaments?

Drying is essential if the filament has absorbed moisture. General safe ranges:

- PLA: 45–55°C for 4–6 hrs

- PETG: 60–65°C for 4–6 hrs

- ABS: 65–80°C for 3–4 hrs

- Nylon: 70–90°C for 8–12 hrs

- TPU: 55–60°C for 4 hrs

How do I safely store filament in India’s humid climate?

Aim for below 15% humidity if possible, though under 30% is okay short-term. During monsoons, when humidity often hits 60–80%, you’ll need extra care:

- Keep spools in vacuum-sealed bags with silica gel

- Use airtight boxes with desiccant packs

- Add a hygrometer to track levels—anything above 40% means it’s time to dehumidify

How do I know if my filament has absorbed too much moisture?

Clear warning signs include:

- Popping or crackling noises during printing

- Filament spitting steam from the nozzle

- Extra stringing or oozing

- Rough or brittle prints

- Poor layer bonding

Can I use a kitchen oven to dry filament?

Yes, but be very cautious. Regular ovens swing in temperature, and PLA can easily deform. If you try this:

- Always check with an external thermometer

- Keep the oven door slightly open so moisture can escape

- Never exceed the recommended drying range

If you want a safe and accurate solution, dedicated dryers like the SUNLU FilaDryer S4 are designed exactly for this job.